As with any new technology, LEDs require some fairly specific background knowledge in order to fully comprehend both the functional properties, and possible methods of application. While everyone here at Inspired LED prides themselves on being knowledgeable enough to answer the most common technical questions regarding our products, there are, of course, times when this technology surprises us with a new challenge. This is when we turn to our resident LED expert- Engineering Manager, Tanner Leland.

As with any new technology, LEDs require some fairly specific background knowledge in order to fully comprehend both the functional properties, and possible methods of application. While everyone here at Inspired LED prides themselves on being knowledgeable enough to answer the most common technical questions regarding our products, there are, of course, times when this technology surprises us with a new challenge. This is when we turn to our resident LED expert- Engineering Manager, Tanner Leland.

Aside from helping us to develop our latest and most innovative products, Tanner is the one we turn to for all things mechanical/electrical. Whether it is a unique customer question, or a particularly complex design, he has the in-depth knowledge and experience to point us in the right direction. This week, he took some time out of his busy schedule to help answer some of our more complicated LED questions. So break out the composition notebooks and put on your thinking caps… things are about to get technical!

Part 1- Basic LED Questions

Question: What exactly is an LED? How does something so small make so much light?

Answer: LED stands for light emitting diode. Like a standard diode, an LED is a semi-conductor composed of a junction of p-type (electron depleted) and n-type (electron rich) semiconductor material that only allows electrical current to flow in one direction. A suitable voltage is required to drive current across this so called p-n junction. The voltage gives the electrons enough energy (known as band-gap energy) to traverse this junction and once they reach the other side, they release the excess energy back into the environment. A standard diode dissipates this energy as heat, whereas an LED dissipates this energy by emitting photons (or light) along with a little bit of heat.

Answer: LED stands for light emitting diode. Like a standard diode, an LED is a semi-conductor composed of a junction of p-type (electron depleted) and n-type (electron rich) semiconductor material that only allows electrical current to flow in one direction. A suitable voltage is required to drive current across this so called p-n junction. The voltage gives the electrons enough energy (known as band-gap energy) to traverse this junction and once they reach the other side, they release the excess energy back into the environment. A standard diode dissipates this energy as heat, whereas an LED dissipates this energy by emitting photons (or light) along with a little bit of heat.

Question: If LEDs dissipate some of their energy through heat, does this mean that my LED system will get hot to the touch?

Answer: Because the process of producing light from an LED is so much more efficient than that of an incandescent bulb, much less heat is generated for the same amount of light. This is what allows the light producing element of an LED to be so much smaller than a traditional bulb without being destroyed by said heat.

Answer: Because the process of producing light from an LED is so much more efficient than that of an incandescent bulb, much less heat is generated for the same amount of light. This is what allows the light producing element of an LED to be so much smaller than a traditional bulb without being destroyed by said heat.

In general, a properly configured LED system will get warm, but should not be hot to the touch. The ambient temperature of an LED will depend on three things: the amount of power applied to the LED, the efficiency of the LED, and the heatsinking capability of the LED’s environment. At Inspired LED, we strive to optimize all of these characteristics in our designs so that we minimize the operating temperature of our LEDs and maximize the longevity of our products.

Question: How do LEDs produce different colors of light?

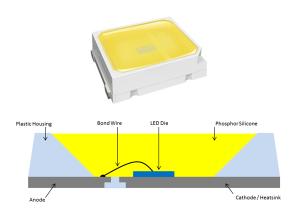

Answer: The photons that are emitted by an LED are of a wavelength proportional to the amount of energy necessary to cross the p-n junction (more energy = shorter wavelength). But producing a specific wavelength means producing only one color at a time. Since white light is a mixture of all of the visible spectrum, from violet at about 390nm to deep red at 700nm, there are certain steps which must be taken in order to produce shades of white from an LED.

Answer: The photons that are emitted by an LED are of a wavelength proportional to the amount of energy necessary to cross the p-n junction (more energy = shorter wavelength). But producing a specific wavelength means producing only one color at a time. Since white light is a mixture of all of the visible spectrum, from violet at about 390nm to deep red at 700nm, there are certain steps which must be taken in order to produce shades of white from an LED.

In order to accomplish this, we start with a blue LED and shine it through a layer of phosphors. These phosphors cause a portion of the blue light to be transformed to light of longer wavelengths (greens, yellows, oranges and reds) through a process called Stokes shift. By tuning the phosphor mixture, the light can be adjusted so that the desired color proportions are achieved – cool white lets through more blue light, while warm white converts more light to red.

Question: Are cool white LEDs naturally brighter than warm white LEDs?

Answer: Because the aforementioned process of shifting blue light through various other colors in order to create white light is not 100% efficient, and because cool white maintains a larger percentage of the original blue, cool white will be slightly brighter using the same amount of power. The difference is typically marginal, and difficult to detect without the proper equipment.

Answer: Because the aforementioned process of shifting blue light through various other colors in order to create white light is not 100% efficient, and because cool white maintains a larger percentage of the original blue, cool white will be slightly brighter using the same amount of power. The difference is typically marginal, and difficult to detect without the proper equipment.

Question: Do LEDs produce UV light?

Answer: They can. One of the beautiful things about LEDs is that they are highly tunable. The wavelength can be pushed anywhere from the ultra violet range to the infrared range. Our LEDs start as blue and some portion of that blue is converted to longer wavelengths by the phosphor coating, so no UV light is created in this process.

Question: Do LEDs burn out? How long do they typically last?

Answer: LEDs themselves tend to fade rather than burn out. LM-80 testing combined with TM-21 projection is the standard for determining the useful life of LEDs, which is accepted to be 70% of the original brightness. LM-80 tests an LED over the course of 6000+ hours and TM-21 uses that data to project how long the LED will stay above 70% of its original brightness. LEDs are often rated between 30,000 and 60,000 hours. However, we try to drive our LEDs at around half of their rating, and in doing so we expect to extend those projected lifetimes significantly.

Answer: LEDs themselves tend to fade rather than burn out. LM-80 testing combined with TM-21 projection is the standard for determining the useful life of LEDs, which is accepted to be 70% of the original brightness. LM-80 tests an LED over the course of 6000+ hours and TM-21 uses that data to project how long the LED will stay above 70% of its original brightness. LEDs are often rated between 30,000 and 60,000 hours. However, we try to drive our LEDs at around half of their rating, and in doing so we expect to extend those projected lifetimes significantly.

LED burnout won’t typically be caused by the LED directly. The failure point in such a situation will almost always be the driver. All LED lighting utilizes a driver to convert from 120VAC to a suitable DC voltage. The drivers are just power supplies, similar to a standard phone charger. LED replacement bulbs typically have them built into the base, while our LED strip light systems operate using a central power supply that drives all of our various lights. The advantage of our approach is the ability to easily replace a power supply and retain all of your lights, making system maintenance simpler and more affordable.

For more information on Inspired LED products and services, visit our website, inspiredled.com, or give us a call at 480-941-4286. Got a technical question about LEDs? Send an email to orders@inspiredled.com and one of our experienced staff members will be happy to assist you!